Predictive Supply Chain Analytics: Seeing the Future of Your Business

In the fast-paced landscape of supply chain management, the ability to gauge and enhance important supply chain metrics is crucial for success. As organizations strive to build a future-proof supply chain, one key tool has emerged as a game-changer: predictive analytics. This comprehensive guide explores the transformative impact of predictive analytics across various industries, shedding light on how it revolutionizes supply chains from reactive entities to proactive powerhouses.

In today’s dynamic business environment, a robust and agile supply chain is no longer a luxury, it’s an imperative. Navigating the complexities of global logistics, fluctuating market trends, and ever-evolving customer demands requires more than just intuition and experience. Enter the realm of predictive analytics, a game-changer that unlocks the power of data to transform supply chains from reactive to proactive powerhouses.

In the intricate environment of supply chain management, envision providing your team with a tool akin to a crystal ball—one that not only illuminates the current state of affairs but also foresees what lies ahead. This visionary tool is none other than predictive analytics, a sophisticated solution that harnesses the power of historical data, machine learning algorithms, and advanced statistical models. Unlike conventional forecasting methods that merely project trends, predictive analytics goes beyond the surface. It dives deep, unveiling hidden patterns, anticipating potential disruptions, and offering actionable insights. This strategic application of predictive analytics empowers your supply chain team to navigate complexities with confidence, ensuring decision-making that extends beyond trend projection to proactively address challenges and optimize strategies for tomorrow.

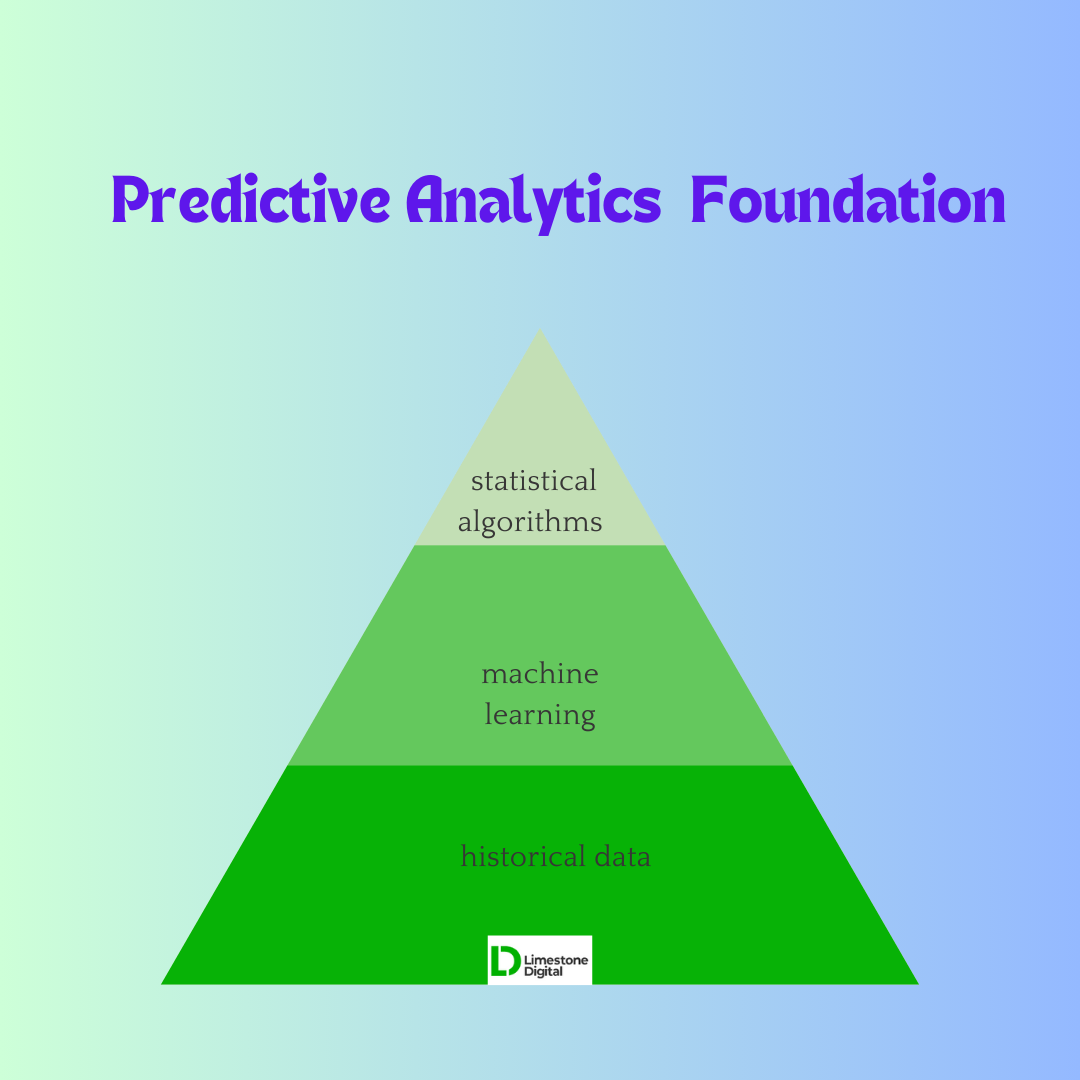

The magic of predictive analytics rests upon three pillars:

Historical data stands as the bedrock of your predictions. This treasure trove encapsulates past performance, trends, and patterns, forming the foundation for a comprehensive understanding of the present and, crucially, the ability to predict future scenarios with precision. When armed with accurate and reliable data, organizations can navigate the complexities of their processes, leveraging insights to make informed decisions and strategically plan for the future.

Within the realm of predictive analytics, machine learning serves as the backbone, encompassing algorithms that meticulously analyze data, discern patterns, and make informed predictions based on emerging information. These sophisticated models transcend traditional approaches, continuously evolving to adapt to changing circumstances and enhance accuracy over time. As a cornerstone of predictive analytics, machine learning empowers organizations to not only understand historical trends but also foresee future scenarios with remarkable precision, making it an indispensable tool for informed decision-making in a dynamic business environment.

In the realm of leveraging predictive analytics, statistical algorithms play a pivotal role in refining predictions, thereby ensuring a heightened level of accuracy in forecasting demand, identifying potential bottlenecks, and optimizing various processes within an organization. This layer of scientific rigor, embedded in statistical analysis, not only enhances the precision of predictions but also guarantees that decisions are firmly grounded in data-driven insights. By leveraging predictive analytics through statistical algorithms, organizations gain a robust analytical framework that empowers them to navigate the intricacies of their operations with strategic foresight and data-driven confidence.

In unison, these three pillars create a formidable foundation for supply chain predictive analytics. The amalgamation of historical data, machine learning prowess, and statistical algorithms not only empowers organizations to understand the dynamics of their supply chain but also equips them with the foresight needed to make proactive, data-driven decisions. This foundation becomes the cornerstone for navigating the intricacies of the supply chain landscape, allowing businesses to streamline processes, mitigate risks, and enhance overall operational efficiency.

Incorporating supply chain predictive analytics into your management processes unleashes a heightened level of agility and efficiency.

You can:

The power of predictive analytics extends far beyond mere demand forecasting. It finds diverse applications across industries, from retail to manufacturing, transforming the way businesses manage their supply chains:

Embracing predictive analytics arms your supply chain management with the foresight derived from historical data, enabling navigation through the ever-changing landscape of your industry. By delving into the insights gleaned from past performance, you gain the ability to anticipate future events, make informed decisions, mitigate risks, and ultimately construct a resilient and adaptable supply chain that excels in the face of any challenge.

While we’ve explored how predictive analytics shines a light on future scenarios and guides informed decisions, let’s dive deeper into one of its most impactful applications: predictive maintenance. Think of it as a sentinel patrolling your own supply chain networks, constantly gathering intelligence and proactively addressing potential threats before they disrupt your operations.

Predictive maintenance leverages a robust trio:

Envision a bustling warehouse where forklifts tirelessly transport goods. Instead of relying on a grinding halt to signal a problem, the predictive maintenance system, powered by analytics in the supply chain, quietly analyzes their energy, fuel consumption, and vibration patterns. Through calculated data analysis, it identifies an impending battery issue in a critical forklift, eliminating guesswork. This proactive approach triggers a timely scheduled maintenance, ensuring uninterrupted operations and preventing costly downtime. This epitomizes the essence of predictive maintenance within the supply chain – it’s not about waiting for breakdowns but employing data as a shield against disruptions. It transforms potential hiccups into strategic opportunities for supply chain optimization.

By integrating predictive maintenance into the purview of your supply chain managers, you unlock a myriad of benefits:

A Real-World Example:Consider a global logistics company where supply chain managers integrated predictive equipment maintenance for a fleet of trucks. Through the analysis of driving patterns, engine data, and environmental factors, the system accurately foresaw potential tire blowouts and engine malfunctions, aligning with future trends in maintenance optimization. This proactive approach empowered supply chain managers to strategically schedule preventative maintenance, resulting in a substantial reduction in roadside breakdowns and ensuring timely deliveries. The tangible outcome was a notable increase in customer contentment and an impressive 12% reduction in operational costs. This real-world application showcases how leveraging predictive analytics and involving supply chain managers can align with future trends, fostering efficiency and stakeholder contentment.

Proactive maintenance, driven by predictive analytics models, transcends technological marvel to become a transformative force for supply chain resilience and effectiveness. Integrating this strategy equips organizations and professionals with the power to anticipate, intervene, and continually improve, thereby constructing a future-proof supply chain designed to excel amid challenges. Embrace the data-driven guardian within your systems, harness the power of proactive care through predictive analytics models, and unlock the full potential of your supply chain..

Predictive analytics paints a vivid picture of the supply chain future, but where do we go from there? Enter prescriptive analytics, the ultimate decision-support system for your supply chain. This advanced tool takes your predictive modeling insights one step further, translating predictions into actionable recommendations, like a GPS for navigating the complexities of your operations.

Source: Garry Killian

Prescriptive analytics uses sophisticated optimization algorithms to analyze the predicted scenarios and recommend the best course of action, considering factors like cost, efficiency, and risk. It can suggest:

The food industry, grappling with distinctive challenges in its supply chain such as perishability concerns and unpredictable weather patterns, finds indispensable solutions through the implementation of supply chain predictive analytics. However, the scope of applications extends well beyond these challenges:

A worldwide food distributor integrated a supply chain predictive analytics platform, monitoring weather patterns and forecasting crop yields. This implementation empowered them to optimize sourcing decisions and negotiate contracts with farmers proactively, anticipating the harvest. Consequently, they achieved a 10% reduction in procurement costs and ensured improved product availability during periods of potential shortages.

These are just a few examples of how predictive analytics is revolutionizing supply chains across industries. By embracing its power, companies can transform their operations from reactive to proactive, optimize resources, identify patterns mitigate risks, and ultimately build a more resilient and sustainable future.

Predictive analytics in supply chains is akin to building a magnificent mansion – but its foundation hinges on valid data. Every insight, every prediction, relies on the accuracy and completeness of the information you feed into the system. Real-time integration is crucial – imagine relying on outdated maps to navigate a fast-changing landscape. Delays in data feeding can lead to misleading predictions and missed opportunities.

The data buffet for your predictive analytics feast is surprisingly diverse. Traditional internal data from sales, inventory, and production flows provides the core ingredients. But there’s much more on the menu:

Transforming this data buffet into actionable insights requires the right tools and technology. Data integration platforms act as the master chef, seamlessly blending various data sources into a unified dish. Cloud computing solutions provide the scalable kitchen, allowing you to handle massive datasets efficiently. And the star ingredient? Powerful analytics tools and machine learning algorithms that decipher the data’s hidden messages and craft accurate forecasts.

A major logistics company implemented a real-time data integration platform, combining internal shipment data with external traffic conditions and weather forecasts. This allowed them to dynamically adjust delivery routes, anticipate delays, and improve on-time delivery rates by 12%.

Demand forecasting, the lifeblood of any supply chain, has undergone a revolution with big data analytics. Leveraging vast datasets and sophisticated algorithms, predictive analytics paints a hyper-realistic picture of future demand, allowing for:

While the potential is immense, implementing big data analytics at scale poses challenges:

However, overcoming these challenges unlocks extraordinary opportunities:

A consumer electronics retailer used big data analytics to predict spikes in demand for specific products based on online reviews and pre-order data. This allowed them to pre-stock popular items at high-demand stores, resulting in a 15% increase in sales during launch week.

The world of predictive analytics is constantly evolving:

By embracing these innovations and overcoming the challenges, businesses can leverage the power of predictive analytics to transform their supply chains into engines of growth and competitive advantage.

Transforming your supply chain with a predictive analytics solution isn’t a technical feat alone; it’s a strategic waltz between data gurus and operational champions. Here’s how to tap into its potential for optimal performance:

First things first, establish your desired dance moves. Do you want to groove with smoother demand forecasting, tango with optimized inventory levels, or salsa with proactive risk mitigation? Clearly defined goals guide your data collection and model selection, ensuring you’re not twirling to the wrong tune.

Forget the lone wolf approach – predictive analytics thrives on collaboration. IT wizards bring the technical expertise, slicing and dicing your data like seasoned DJs. Supply chain pros, then, act as the floor generals, translating insights into operational moves. This dynamic duo ensures your supply chain dances to the rhythm of accurate forecasts.

Not all tracks are created equal. Different industries and goals require specific analytical tools. Retailers might waltz with granular demand forecasting models, while manufacturers might tap into equipment failure prediction algorithms. Work with your IT counterparts to choose the tools that fit your supply chain’s groove.

Imagine trying to tango on a cobblestone street – data quality issues can cripple your efforts. Ensure your data is clean, consistent, and integrated across sources. This forms the smooth surface on which your predictive models can gracefully glide.

Don’t try the triple flip before mastering the basic steps. Start with small-scale pilot projects, testing different models and refining your approach. Embrace continuous improvement like a dedicated dance coach, iterating on your models and learning from feedback to achieve supply chain mastery.

By following these steps and learning from real-world examples, you can transform your supply chain management from a clunky waltz to a graceful, evidence-based tango, optimizing performance, minimizing risks, and outmaneuvering the competition. Remember, predictive analytics is your partner in this dance – embrace its power and unlock the full potential of your supply chain to thrive in the ever-evolving business landscape.

In the fiercely competitive business world, a resilient and efficient supply chain management is no longer a luxury, it’s an imperative. Implementing predictive analytics across industries unlocks a treasure trove of measurable benefits:

These are just a few examples – the possibilities are endless. By embracing predictive analytics, companies across diverse sectors can revolutionize their supply chains, gain a competitive edge, and achieve sustainable growth.

In today’s dynamic business landscape, the future of supply chains belongs to those who embrace data-driven insights. Predictive analytics is not just a technological fad; it’s a transformative tool that empowers businesses to navigate uncertainty with confidence, optimize operations for peak efficiency, and build resilient supply chains that thrive in the face of any challenge.

Imagine a world where supply chains dance to the rhythm of accurate forecasts, where disruptions are anticipated and mitigated before they even arise, and where customer satisfaction soars on the wings of personalized experiences. This is the future that predictive analytics unlocks, and it’s a future within reach for any company willing to embrace its power.

At Limestone Digital, we understand the transformative potential of predictive analytics. We offer customized IT solutions tailored to your specific industry and supply chain management needs. From choosing the right strategy and integrating supply chain data to building robust models and optimizing processes, our team of experts is here to partner with you on your journey towards an evidence-based, resilient, and future-proof supply chain.

Don’t let the tide of change leave you behind. Embrace the power of predictive analytics with Limestone Digital, and together, let’s rewrite the future of your supply chain.

Visit our website or contact us today for a free consultation and discover how Limestone Digital can help you unlock the transformative power of predictive analytics for your supply chain processes.

- 27 mins read

Master financial app development! Our guide covers everything: niche identification, user-friendly features, security best practices, navigating regulations, and fostering consumer growth. Build the app that empowers users and shapes the future of finance.

- 16 mins read

This comprehensive guide will equip you with everything you need to know about eLearning app development services. We'll delve into the world of education app development companies, explore the functionalities that make eLearning solutions effective, and showcase the range of options available to create your ideal learning experience.

- 26 mins read

Discover AI's transformation of e-commerce: enhanced shopping, personalized experiences, and optimized operations in 'E-Commerce 2.0: AI's Role in Online Retail Efficiency.